2017 Eastern Metallizing Co Pvt Limited All rights reserved.

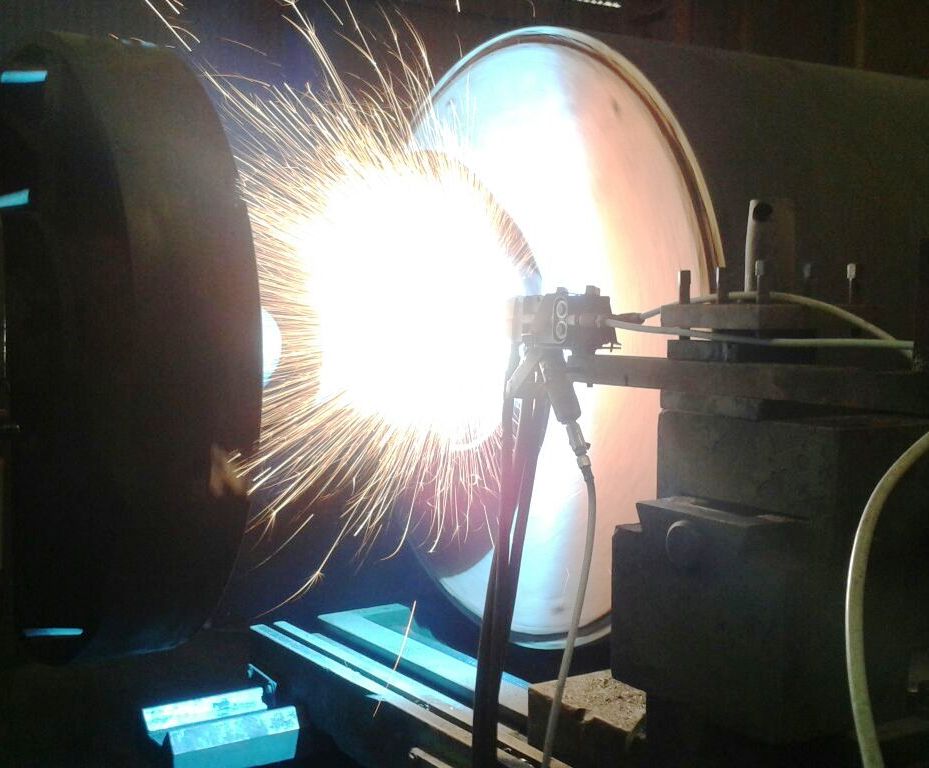

What is Thermal Spray

...............................................................................................................................................

Thermal Spray is a process by which desired feedstock material (metallic, non-metallic,

carbides, ceramics, cermets etc) are melted / softened and propelled towards the substrate

material to form a dense, cohesively bonded layer, imparting superior / desired properties

to the surface of the substrate vis a vis the properties of the base material. Depending

upon the application and material being sprayed, different forms of Thermal spray coatings

are recommended

We at EMC have the capability and know how to spray almost all possible materials including

Metallic, Non-Metallic, Ceramics, Carbides, CERMETS etc

...............................................................................................................................................

Thermal Spray Processes at Eastern Metallizing

...............................................................................................................................................

- HVOF - For Tungsten Carbides, Chrome Carbides, Proprietary alloys etc

- Twin Wire Arc Spray - For ferrous coatings

- Rod and Powder Flame Spray - used for Ceramic Coatings

- Gas Flame Spray - For non-ferrous coatings

...............................................................................................................................................

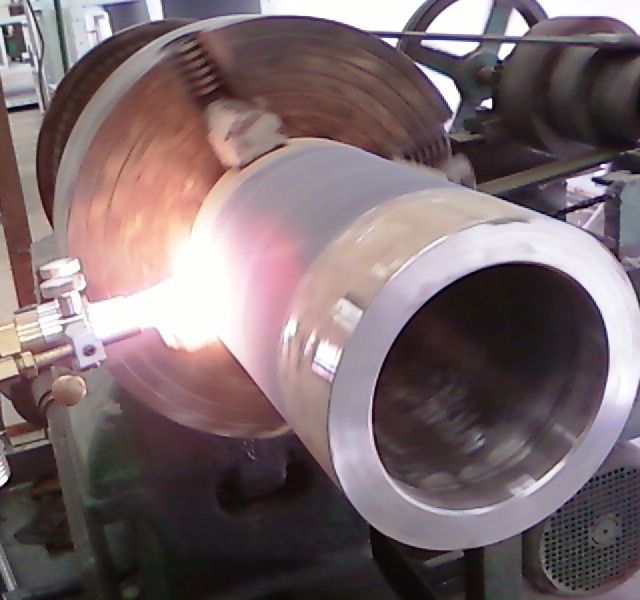

Grinding & Finishing of Thermal Spray Coatings

...............................................................................................................................................

At Eastern Metallizing, we have the machinery capability and the know how to Grind all coatings;

- HVOF - Ground using our CNC grinding to <=0.1 microns Ra

- Ceramics - Ground using our CNC / conventional grinding to <=0.8 microns Ra

- Ferrous Coatings - Ground using our CNC grinding to <=0.5 microns Ra

- Ferrous Coatings - Machined using our CNC Turning to <=0.8 microns Ra

- Non- Ferrous Coatings - Machined using our CNC Turning to <=0.8 microns Ra

...............................................................................................................................................